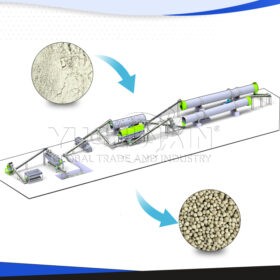

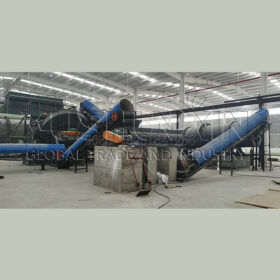

Linia do produkcji nawozów wapiennych polega na wytwarzaniu granulatów wapienia lub granulatów węglanu wapnia. Zwykle składa się z kilku etapów, łącznie z frezowaniem, ekranizacja, Mieszanie, Granulowanie, wysuszenie, i chłodzenie. Nawóz wapienny jest powszechnie stosowany w celu dostosowania poziomu pH gleby i zapewnienia roślinom źródła wapnia.

Proces pracy

Przemiał: Skały wapienne są frezowane 200 proszki siatkowe z młyna Raymond.

Mieszanie: Proszek wapienny należy mieszać z innymi składnikami, takimi jak azotan amonu, fosforan, i potas, aby stworzyć kompletną mieszankę nawozów. Ilość każdego użytego składnika będzie zależała od konkretnego składu nawozu.

Granulacja: Następnie mieszaninę nawozów można granulować w celu utworzenia małych peletek, które są łatwiejsze w obsłudze i stosowaniu. Można tego dokonać stosując granulator talerzowy lub granulator z mieszadłem kołkowym ze spoiwem.

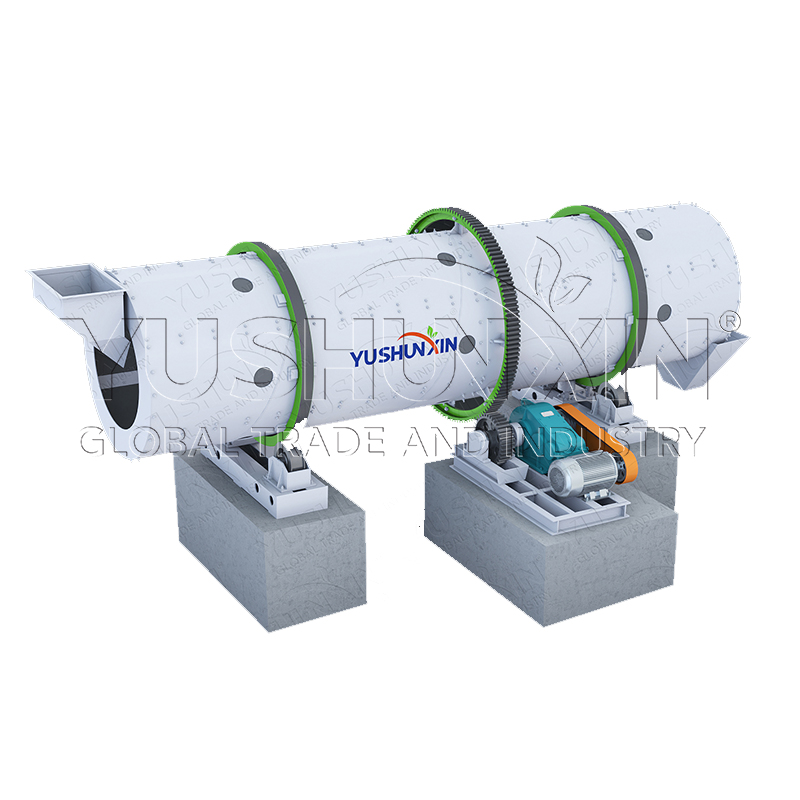

Wysuszenie: Za pomocą suszarki obrotowej, granulowany nawóz suszy się w celu usunięcia nadmiaru wilgoci.

Chłodzenie i ekranowanie: Wysuszony granulat nawozu jest schładzany i przesiewany w celu usunięcia pyłu i drobnych cząstek.

Pakowanie i przechowywanie: Gotowy granulowany nawóz wapienny (rozpuszczalny w wodzie) są pakowane i przechowywane w suchym i chłodnym miejscu.

Linia do produkcji nawozów wapiennych ma charakter mniejszych inwestycji, szybkie rezultaty i dobre korzyści ekonomiczne. Cały proces wyposażenia jest kompaktowy, naukowe i zaawansowane. Oszczędność energii i zmniejszenie zużycia, żadnego wywozu śmieci, stabilna praca, niezawodne działanie, wygodna konserwacja.