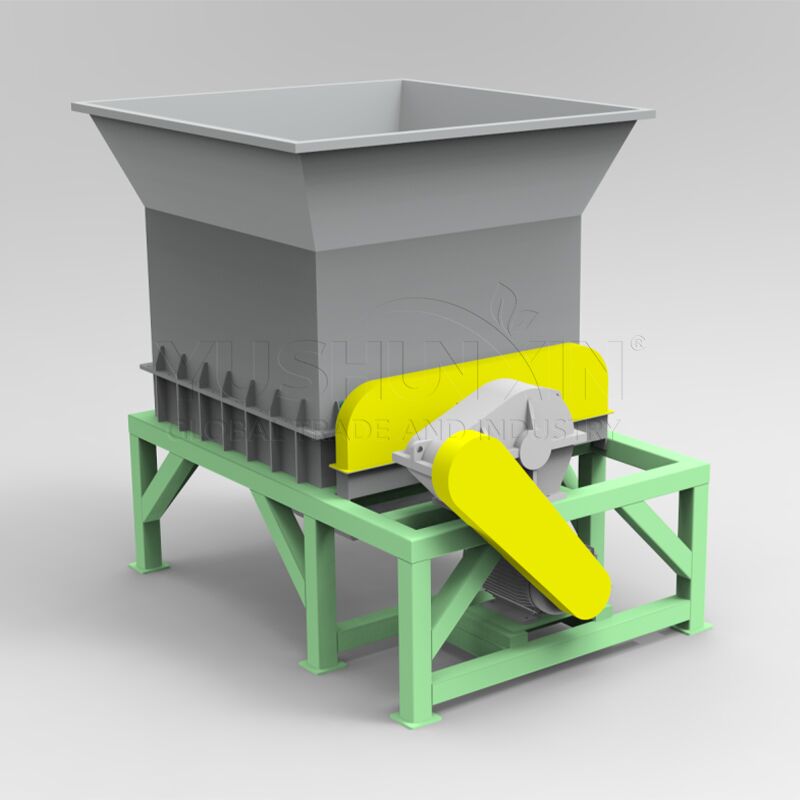

The Fertilizer Bulk Bag Lump Breaker is specially designed for breaking hardened lumps and compacted fertilizer materials discharged from bulk bags (FIBC / jumbo bags). It effectively restores fertilizer materials to a free-flowing state, ensuring smooth and continuous feeding for downstream processes such as conveying, blending, granulation or packaging.

Fertilizers are prone to caking due to moisture absorption and long-term storage. This machine adopts a low-speed, high-torque crushing system to gently break fertilizer lumps without excessive fines generation, preserving material quality and reducing dust.

The lump breaker can be installed directly under a bulk bag unloading station and integrated into automated fertilizer production lines.

Key Features

1.Designed specifically for caked fertilizer materials

2.Efficiently breaks large lumps formed by moisture or pressure

3.Low-speed operation minimizes dust and material degradation

4.High-torque drive suitable for hard and compacted fertilizer blocks

5.Continuous and uniform material discharge

6.Heavy-duty alloy steel shafts and cutters for long service life

7.Compatible with screw conveyors, belt conveyors or feeding systems

8.Optional corrosion-resistant and explosion-proof configurations

Zasada pracy

Fertilizer material discharged from the bulk bag falls into the crushing chamber of the lump breaker. One or two rotating shafts equipped with specially designed cutters operate at low speed and high torque.

As the fertilizer lumps pass through the chamber, they are sheared, compressed and torn apart by the cutters, reducing large agglomerates into smaller, free-flowing particles. The processed material then falls evenly through the outlet into the downstream conveying or processing equipment.

This gentle crushing process ensures effective de-lumping while preventing over-grinding and excessive dust generation.