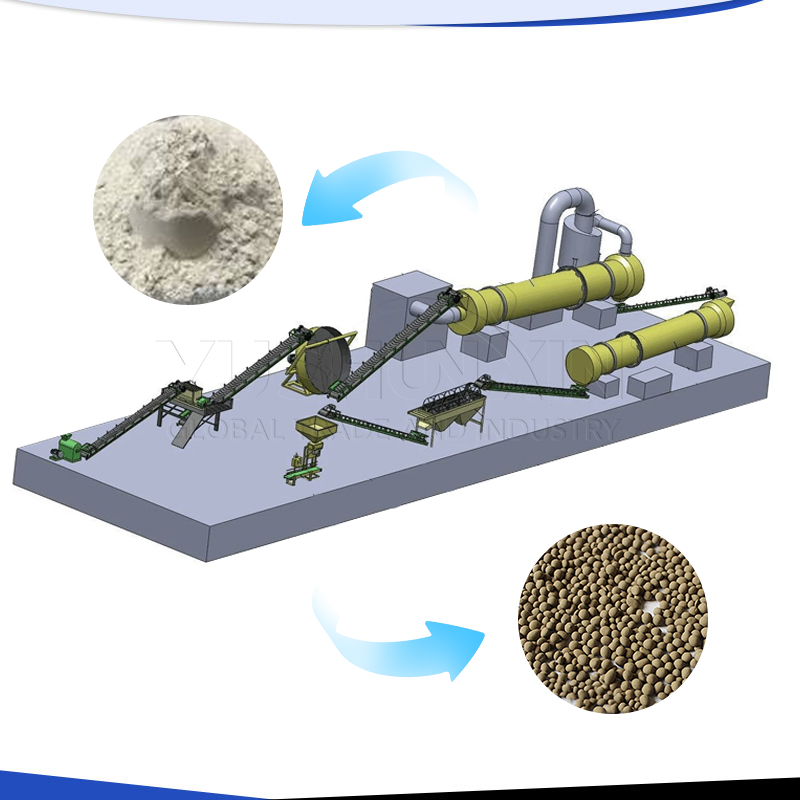

La ligne de production de litière pour chat fait référence au processus complet et à l'ensemble des équipements utilisés pour fabriquer de la litière pour chat, depuis les matières premières jusqu'aux produits finis emballés.. Il se compose généralement de plusieurs étapes, y compris le broyage, dépistage, Mélange, granulation, séchage, et refroidissement.

Processus de travail

1. Manutention des matières premières: Le processus de production commence par la manipulation des matières premières. Les matériaux couramment utilisés pour la litière pour chats comprennent l'argile (bentonite), gel de silice, papier recyclé, copeaux de bois, ou d'autres substances biodégradables. Les matières premières doivent être nettoyées, séché, et filtré pour éliminer les impuretés et assurer la cohérence.

2.Mélange: Une fois préparé, les matières premières sont mélangées selon une formule spécifique. Le processus de mélange est crucial pour obtenir les caractéristiques souhaitées de la litière pour chat, comme la capacité d'agglutination, contrôle des odeurs, et capacité d'absorption. Des additifs comme des neutralisants d'odeurs ou des colorants peuvent également être incorporés à cette étape..

3.Granulation: Le matériau mélangé est ensuite traité via un équipement de granulation pour donner aux particules de litière pour chat la taille et la forme souhaitées.. Cette étape peut impliquer une extrusion, granulation, ou d'autres techniques de formage en fonction du type de litière pour chat produite.

4. Séchage: Après granulation, les particules de litière pour chat sont séchées pour réduire la teneur en humidité. Cela contribue à améliorer la stabilité du produit, empêcher la croissance microbienne, et assurez-vous que la litière conserve ses propriétés souhaitées pendant le stockage et l'utilisation.

5. Conditionnement: Une fois séché, la litière pour chat est prête à être emballée. L'emballage peut être effectué à l'aide de systèmes automatisés qui remplissent des sacs ou des boîtes avec la litière pour chat., et les étiquettes peuvent être appliquées conformément aux exigences de la marque..

6. Stockage et distribution: Enfin, les produits de litière pour chats emballés sont stockés dans des entrepôts et préparés pour être distribués aux détaillants ou directement aux consommateurs.

Salut, veuillez fournir les spécifications et les prix

Merci