ะะธะฝะธั ะฟะพ ะฟัะพะธะทะฒะพะดััะฒั ะดัะตะฒะตัะฝะพะณะพ ัะณะปั ะฟัะตะดััะฐะฒะปัะตั ัะพะฑะพะน ะบะพะผะฟะปะตะบัะฝัั ัะธััะตะผั, ะฟัะตะดะฝะฐะทะฝะฐัะตะฝะฝัั ะดะปั ะฟัะตะพะฑัะฐะทะพะฒะฐะฝะธั ััััั ะผะฐัะตัะธะฐะปะพะฒ ะฑะธะพะผะฐััั ะฒ ะดัะตะฒะตัะฝัะน ัะณะพะปั ะฟะพััะตะดััะฒะพะผ ะฟัะพัะตััะฐ, ะฝะฐะทัะฒะฐะตะผะพะณะพ ะบะฐัะฑะพะฝะธะทะฐัะธั (ะฟะธัะพะปะธะท). ะญัะฐ ะฟัะพะธะทะฒะพะดััะฒะตะฝะฝะฐั ะปะธะฝะธั ัะธัะพะบะพ ะธัะฟะพะปัะทัะตััั ะดะปั ะธะทะณะพัะพะฒะปะตะฝะธั ะฃะณะพะปั ะดะปั ะฑะฐัะฑะตะบั, ัะณะพะปั ะดะปั ะบะฐะปััะฝะฐ, ัะตั ะฝะธัะตัะบะธะน ัะณะพะปั, ะธ ะฑะธะพัะณะพะปั.

ะัะฟะพะปัะทัั ัะพะฒัะตะผะตะฝะฝะพะต ะพะฑะพััะดะพะฒะฐะฝะธะต, ะฟัะพะธะทะฒะพะดััะฒะตะฝะฝัะน ะฟัะพัะตัั ััะฐะฝะพะฒะธััั ัััะตะบัะธะฒะฝัะน, ัะบะพะปะพะณะธัะตัะบะธ ัะธัััะน, ะธ ัะบะพะฝะพะผะธัะตัะบะธ ัััะตะบัะธะฒะฝัะน, ัะดะตะปะฐัั ะตะณะพ ะฟัะธะฑัะปัะฝัะผ ะฑะธะทะฝะตัะพะผ ะฒ ัะฐะทะปะธัะฝัั ะพััะฐัะปัั .

ะะปััะตะฒัะต ะบะพะผะฟะพะฝะตะฝัั ะปะธะฝะธะธ ะฟะพ ะฟัะพะธะทะฒะพะดััะฒั ะดัะตะฒะตัะฝะพะณะพ ัะณะปั

-

ะะพะดะณะพัะพะฒะบะฐ ััััั

-

ะะฐัะตัะธะฐะปั ะฑะธะพะผะฐััั, ัะฐะบะธะต ะบะฐะบ ะดัะตะฒะตัะธะฝะฐ, ะบะพะบะพัะพะฒะฐั ัะบะพัะปัะฟะฐ, ะพะฟะธะปะบะธ, ะธ ะฑะฐะผะฑัะบ ัะพะฑะธัะฐัััั ะธ ะพะฑัะฐะฑะฐััะฒะฐัััั.

-

ะ ะดัะพะฑะธะปะบะฐ ะธะปะธ ะธะทะผะตะปััะธัะตะปั ะดัะตะฒะตัะธะฝั ะธัะฟะพะปัะทัะตััั ะดะปั ะธะทะผะตะปััะตะฝะธั ะบััะฟะฝัั ะผะฐัะตัะธะฐะปะพะฒ ะฝะฐ ะฑะพะปะตะต ะผะตะปะบะธะต ะบััะบะธ..

-

-

ะัะพัะตัั ัััะบะธ

-

ะะปะฐะถะฝะพััั ััััั ัะฝะธะถะฐะตััั ั ะฟะพะผะพััั ะฒัะฐัะฐััะฐััั ะฑะฐัะฐะฑะฐะฝะฝะฐั ัััะธะปะบะฐ ะธะปะธ ะพัััะธัะตะปั ะฒะพะทะดััะฝะพะณะพ ะฟะพัะพะบะฐ ะดะปั ะฟะพะฒััะตะฝะธั ัััะตะบัะธะฒะฝะพััะธ ะบะฐัะฑะพะฝะธะทะฐัะธะธ.

-

-

ะะฐัะฑะพะฝะธะทะฐัะธั (ะะธัะพะปะธะท)

-

ะััััะตะฝะฝัะต ะผะฐัะตัะธะฐะปั ะฝะฐะณัะตะฒะฐัั ะฒ ะฟะตัั ะดะปั ะบะฐัะฑะพะฝะธะทะฐัะธะธ ะดัะตะฒะตัะฝะพะณะพ ัะณะปั ะฟัะธ ะฒััะพะบะธั ัะตะผะฟะตัะฐัััะฐั (300-600ยฐะก) ะฒ ััะตะดะต ั ะฝะธะทะบะธะผ ัะพะดะตัะถะฐะฝะธะตะผ ะบะธัะปะพัะพะดะฐ.

-

ะญัะพั ะฟัะพัะตัั ะฟัะตะฒัะฐัะฐะตั ะฑะธะพะผะฐััั ะฒ ะดัะตะฒะตัะฝัะน ัะณะพะปั ะธ ะฟัะพะธะทะฒะพะดะธั ะณะพัััะธะต ะณะฐะทั, ะบะพัะพััะต ะผะพะถะฝะพ ะธัะฟะพะปัะทะพะฒะฐัั ะฟะพะฒัะพัะฝะพ..

-

-

ะะฑััะตะฝะธะต ะฑัะธะบะตัั (ะะตะพะฑัะทะฐัะตะปัะฝัะน)

-

ะัะปะธ ะฟัะพะธะทะฒะพะดะธัั ะฑัะธะบะตั ะดัะตะฒะตัะฝัะน ัะณะพะปั, ะฟะพัะพัะบะพะพะฑัะฐะทะฝัะน ัะณะพะปั ัะผะตัะธะฒะฐะตััั ัะพ ัะฒัะทัััะธะผะธ ะฒะตัะตััะฒะฐะผะธ ะธ ะฟัะตัััะตััั ะฒ ัะฐะทะปะธัะฝัะต ัะพัะผั ั ะฟะพะผะพััั ะผะฐัะธะฝะฐ ะดะปั ะธะทะณะพัะพะฒะปะตะฝะธั ะฑัะธะบะตัะพะฒ.

-

ะะฑัะธะต ัะพัะผั ะฒะบะปััะฐัั ะฒ ัะตะฑั ะบัะฑะธะบะธ, ัะตััะธัะณะพะปัะฝะธะบะธ, ะฒ ัะพัะผะต ะฟะพะดััะบะธ, ะธ ััะตัะถะฝะธ.

-

-

ะั ะปะฐะถะดะตะฝะธะต & ะะพะปะปะตะบัะธั

-

ะะพัััะธะน ัะณะพะปั ะพั ะปะฐะถะดะฐะตััั ั ะฟะพะผะพััั ัะธััะตะผะฐ ะพั ะปะฐะถะดะตะฝะธั ัะณะปั ะดะปั ะฟัะตะดะพัะฒัะฐัะตะฝะธั ัะฐะผะพะฒะพะทะณะพัะฐะฝะธั.

-

-

ะฃะฟะฐะบะพะฒะบะฐ & ะ ะฐัะฟัะตะดะตะปะตะฝะธะต

-

ะะพะฝะตัะฝัะน ะฟัะพะดัะบั ัะฟะฐะบะพะฒัะฒะฐะตััั ั ะธัะฟะพะปัะทะพะฒะฐะฝะธะตะผ ัะฟะฐะบะพะฒะพัะฝะฐั ะผะฐัะธะฝะฐ ะดะปั ั ัะฐะฝะตะฝะธั ะธ ะฟัะพะดะฐะถะธ.

-

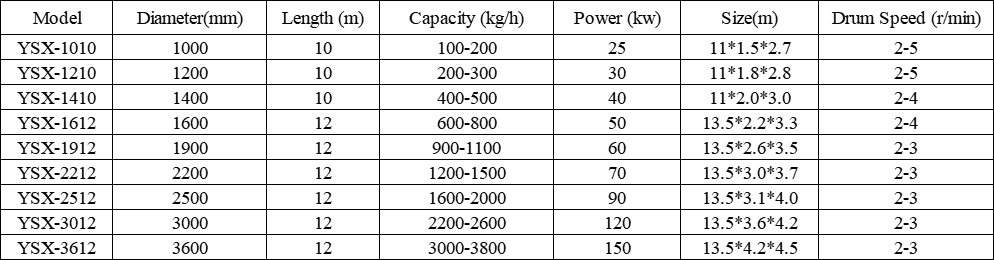

ะกะบะพะปัะบะพ ััะพ ััะพะธั?

ะะฝัะตัะตััะตั ะปะธะฝะธั ะฟะพ ะฟัะพะธะทะฒะพะดััะฒั ะดัะตะฒะตัะฝะพัะณะพะปัะฝัั ะฑัะธะบะตัะพะฒ..

ะกะฟะฐัะธะฑะพ