The charcoal production line is a complete system designed to convert raw biomass materials into charcoal through a process called carbonization (pyrolysis). This production line is widely used for making BBQ charcoal, shisha charcoal, industrial charcoal, and biochar.

By utilizing advanced equipment, the production process becomes efficient, eco-friendly, and cost-effective, making it a profitable business in various industries.

Key Components of Charcoal Production Line

-

Pregatirea materiei prime

-

Biomass materials such as wood, coconut shells, sawdust, and bamboo are collected and processed.

-

A crusher or wood chipper is used to reduce large materials into smaller pieces.

-

-

Drying Process

-

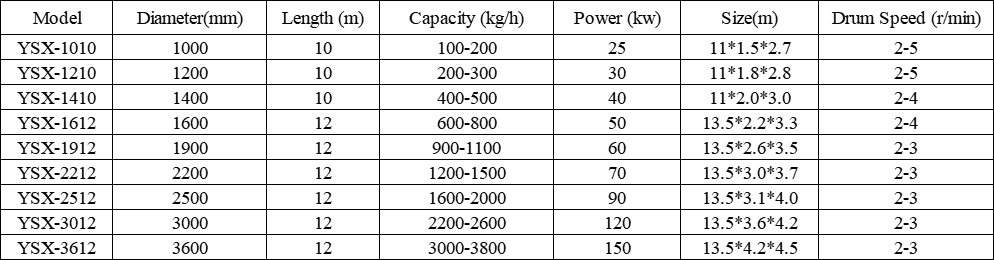

The moisture content of raw materials is reduced using a rotary drum dryer or airflow dryer to improve carbonization efficiency.

-

-

Carbonization (Pyrolysis)

-

The dried materials are heated in a charcoal carbonization furnace at high temperatures (300-600°C) in a low-oxygen environment.

-

This process transforms biomass into charcoal while producing combustible gases that can be reused.

-

-

Briquette Formation (Optional)

-

If producing briquette charcoal, the powdered charcoal is mixed with binders and pressed into different shapes using a briquette-making machine.

-

Common shapes include cubes, hexagons, pillow-shaped, and rods.

-

-

Cooling & Collection

-

The hot charcoal is cooled using a charcoal cooling system to prevent spontaneous combustion.

-

-

Ambalare & Distribution

-

The final product is packaged using a packing machine for storage and sale.

-

كم سعرها

Am interested in the charcoal briquette making production line.

Thank you