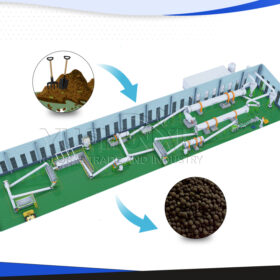

Il rapido sviluppo del bestiame e dell'allevamento di pollame produce molti escrementi e liquami. Gli elementi dannosi di questi incrostazioni sono troppo alti per essere elaborati dalla tradizionale via di ritorno. Per questa situazione, La nostra azienda ha sviluppato la linea di produzione di fertilizzanti organici che utilizza la tecnologia di deodorizzazione asettica marcia solida altamente efficiente come core, e l'intero processo di attrezzatura di produzione come segue:

1.Pre-elaborazione della materia prima: Materiali biologici come i rifiuti animali, residui di colture, Suddi, Filtro fango, La torta di Dregs Sugar viene raccolta e pre-elaborata. Ciò può comportare il disturbo, schiacciamento, o asciugare per facilitare la manipolazione e la fermentazione successive.

2.Fermentazione: I materiali organici pre-elaborati subiscono una fermentazione per decomporre la materia organica e convertirla in composti organici stabili. Questo processo viene generalmente eseguito in serbatoi di fermentazione o tornitori di compost in condizioni di temperatura controllate, umidità, e aerazione.

3.Schiacciamento e miscelazione: Dopo la fermentazione, I materiali organici possono subire ulteriori elaborazioni come la frantumazione e la miscelazione per ottenere dimensioni uniformi delle particelle e fondere materiali diversi per ottenere la composizione nutritiva desiderata.

4.Granulazione: I materiali organici misti vengono quindi alimentati in una macchina di granulazione per formare granuli di dimensioni e forma uniformi. La granulazione aiuta a migliorare la gestione, magazzinaggio, e applicazione di fertilizzanti organici e garantisce il rilascio di nutrienti controllati.

5.Asciugatura: I granuli appena formati possono contenere umidità in eccesso, che deve essere ridotto per migliorare la loro stabilità e la durata di conservazione. I granuli sono in genere essiccati in asciugatrici rotanti o altre attrezzature di essiccazione fino a raggiungere il contenuto di umidità desiderato.

6.Raffreddamento: Dopo essiccarsi, I granuli vengono raffreddati a temperatura ambiente per impedire loro di tagliare o stare insieme durante lo stoccaggio e il trasporto. Attrezzatura di raffreddamento come refrigeratori di tamburi rotanti o dispositivi di raffreddamento a letto fluidizzato è comunemente usato a questo scopo.

7.Screening e classificazione: I granuli raffreddati vengono sottoposti a screening per rimuovere particelle di grandi dimensioni o sottodimensionate e garantire l'uniformità del prodotto. La classificazione può anche essere effettuata in granuli separati in frazioni di dimensioni diverse per applicazioni specifiche.

8.Imballaggio e archiviazione: L'ultimo passo nella linea di produzione di fertilizzanti organici prevede l'imballaggio dei granuli in borse, sacchi, o altri contenitori per la distribuzione e la vendita. L'imballaggio adeguato aiuta a mantenere la qualità del prodotto e prolungare la durata di conservazione. I fertilizzanti confezionati vengono quindi conservati in un magazzino o spediti direttamente ai clienti.

letame di maiale altri rifiuti organici

video. Informazioni tecnologiche. prezzo

Frugni dall'impianto di trattamento delle acque reflue

Fertilizzante

Sono interessato e sono molto apprezzato da The Allah

Letame di pollo

Sono interessato alla macchina di produzione di biofertilizer. Si prega di inoltrare l'aggiornamento sul costo e sulla consegna in Nigeria

CIAO:

Sono Willy Cornejo de Boliva -Santa Cruz, vorrei contattare la tua azienda in modo da poter visitare la tua azienda. Nel mese di ottobre

Gracias

Questo molto encomiabile e mi piacerebbe saperne di più, forse addestrati sulla tecnica di elaborazione.

Molto interessante e quanto è installato questo impianto e in funzione.

Maggiori dettagli e prezzo

Machine di letame mouton

macchina per letame di maiale

Sterco di mucca

Granulo e copertura con umico

Rifiuti organici in generale: letame di maiale, sterco di mucca, rifiuti di mango, Banane rifiuti.

Compresa la spedizione a Cartagena Colombia

Bioonivo SAS Agroinsum

Letame da allevamento da latte 5 tonnellate all'ora

Tipo di prodotto che offri

letame di pollo, sterco di mucca, 🐑 letame

1 O 5 tonnellate all'ora

pollo, mucca di maiale 5 tonnellate all'ora

Elettricità Apparecchiature richieste

Soluzioni integrate & Consulenza per lo sviluppo

Ciao questo è raffaello,vuoi i dettagli e il prezzo

La linea di fertilizzanti organici mira a costruire straordinari della salute del suolo

5 to20t

5 Viene applicato a 20 toni per ecter del compost

Urea come fertilizzante composto

Tipi meny di materie prime. Ma la maggior parte di esso lo spreco di pecore 5 tonnellate all'ora

è un lavoro per fole o elecarità

sterco di mucca, letame di pollo e letame di pecora

Essiccatore di pollo e sterco di pecora

scavati di pollo e mucca

Letame di pollo , letame di maiale , Letame di mucche e altri prodotti biologici

letame a goccia 1 ora di tono

I’m very interested